Are you exposed to risk?

Lasers make a lot possible. But they can also generate undesirable particulate and gaseous matter—fumes. Particulate can be less than 5 microns wide and invisible to the naked eye. This means it’s breathable and, left unchecked, could pose a risk to your employees. Safety matters. That’s why Raymax Lasers not only assists you with selecting the most suitable laser system but also a fume extractor to go with it.

Where laser fumes come from

Lasers are replacing traditional methods of processing materials in many industries. They often provide greater precision and innovation than traditional methods, with reduced waste. Lasers cut, mark, drill, coat, build and weld a wide range of materials. Metals are the most common substrate, but organic materials like plastics, paper, and wood are catching up fast. In performing virtually all of these tasks, the laser breaks down the materials it’s working on (even if that’s in micro amounts), and fumes are released. These fumes need to be safely removed from your workplace.

Laser applications that generate fumes

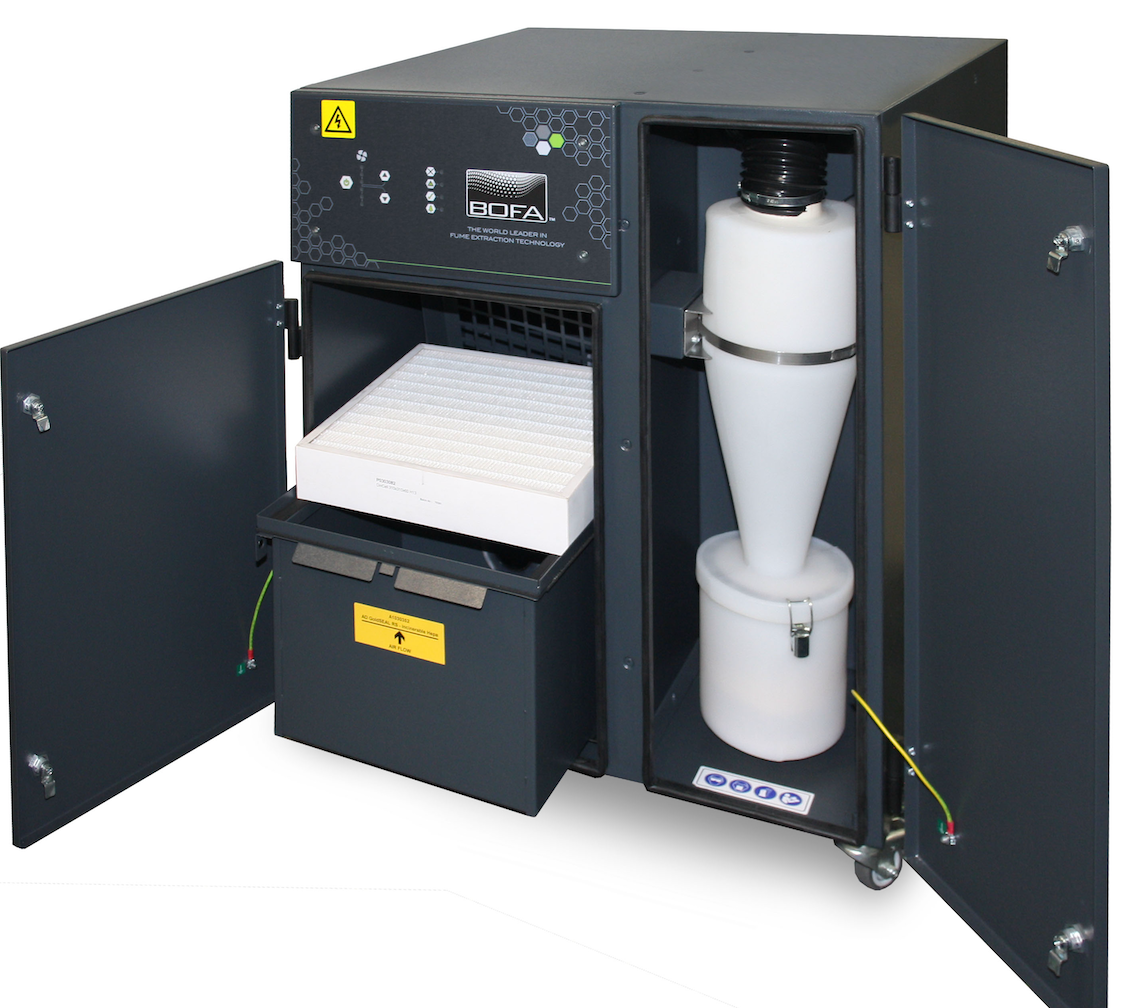

It’s not only laser marking, cutting, and welding that creates these fumes. 3D printing also projects gases and particles which could be inhaled by the operator. If you’re not sure whether your laser system emits harmful fumes, contact us. Raymax supplies BOFA laser fume extractors for improved air quality. BOFA is an award-winning company; their Advantage range is designed for applications that generate particulate and gaseous organic compounds.

Protect your people AND production

Fumes aren’t just harmful to the health of your employees. They can also disrupt production. Particles from 3D printing can build up in the machine. The result? More maintenance and potential delays to production. Similarly, if particulate burns onto the lens of an optical system, it risks the efficacy of your laser. Protect your valuable laser equipment with a BOFA laser fume extractor from Raymax.

Help avoid contamination

Another laser beam hazard to consider could be contamination. This is especially important if you’re marking a container that will be filled. The contaminants could settle in the container and infiltrate whatever it’s filled with. Fume extraction can help you control the Laser-generated Airborne Contaminants (LGACs), so your products remain clean and you remain compliant.

Green technology

Lasers are generally a green technology, and the use of a suitable extractor keeps it that way—no smoke, no dust, no problem. In many ways, laser technology is better for the environment. It has the potential to decrease waste in manufacturing and the replacement of parts. This is great news for companies looking for ways to reduce their ecological footprint.

Why Raymax?

We make laser light work for you. We’ve spent over 30 years demonstrating what’s possible with lasers. In doing so, we’ve helped modernise Australian and New Zealand industries. You’ll be working with a team of physicists and factory-trained engineers—leaders in the supply of laser solutions and photonics equipment. We’re experts in material interaction research. Wherever possible, you’ll be introduced to new technology that can improve operation in ways you might not have imagined possible.

Speak to an expert

Enter your details and we’ll get in touch to discuss your needs.Book a Consultation

Contact Us

(02) 9979 7646

Visit Us

37/5 Ponderosa Parade Warriewood NSW 2102