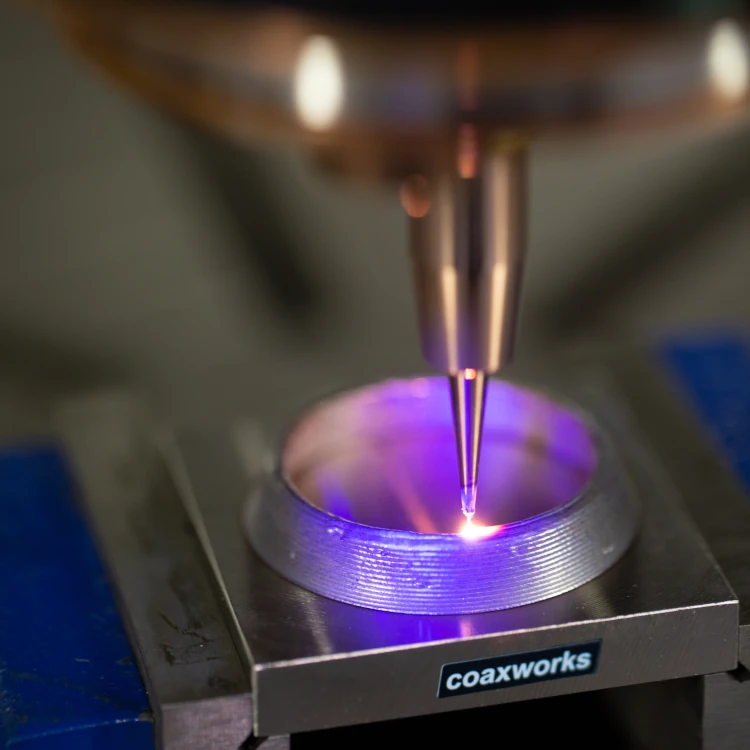

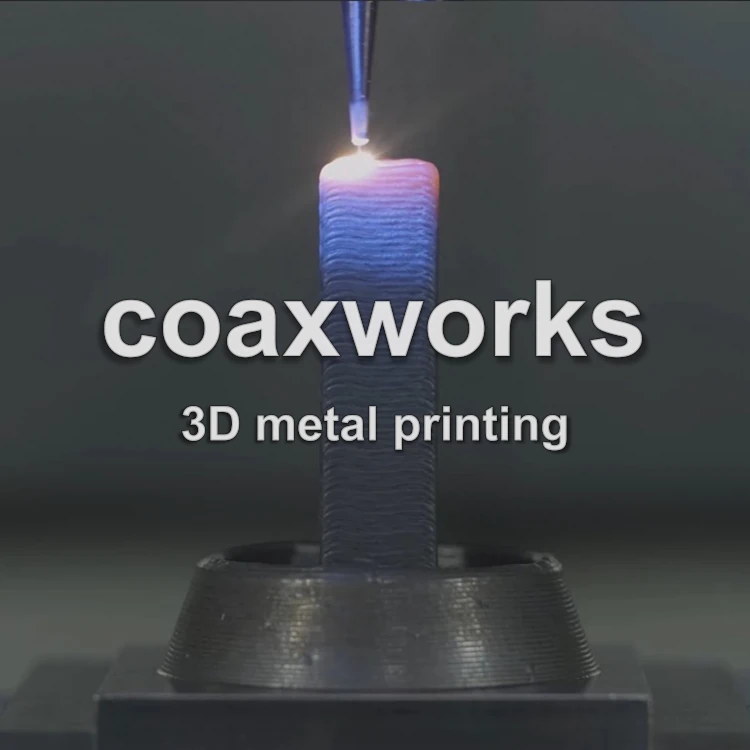

Laser welding heads for laser wire deposition, 3D metal printing and more

coaxworks GmbH, founded in 2018, is our innovative partner for system technology and services of the technology of direction-independent laser wire deposition. They offer both standard and customised multi-beam laser welding heads with centric wire feed for cladding processes like coating, repairing and generating. Whether as a retrofit for your laser cell, as an upgrade for your welding robot or as a mounting kit for your production machines – there are numerous options for integration.

Process advantages:

- Flexible and direction-independent welding with robust3‑beam design

- Productive processes with up to 4 kW laser power and up to 2.5 kg/h deposition rate

- Minimal material influence on the workpiece due to precise laser beam

Integration advantages:

- Clean, resource-saving and low-maintenance installation solution through 100% utilisation of the filler wire

- Reproducible and long-term constant manufacturing quality due to automated mode of operation

- Collision protection integrated into laser welding head to avoid machine damage

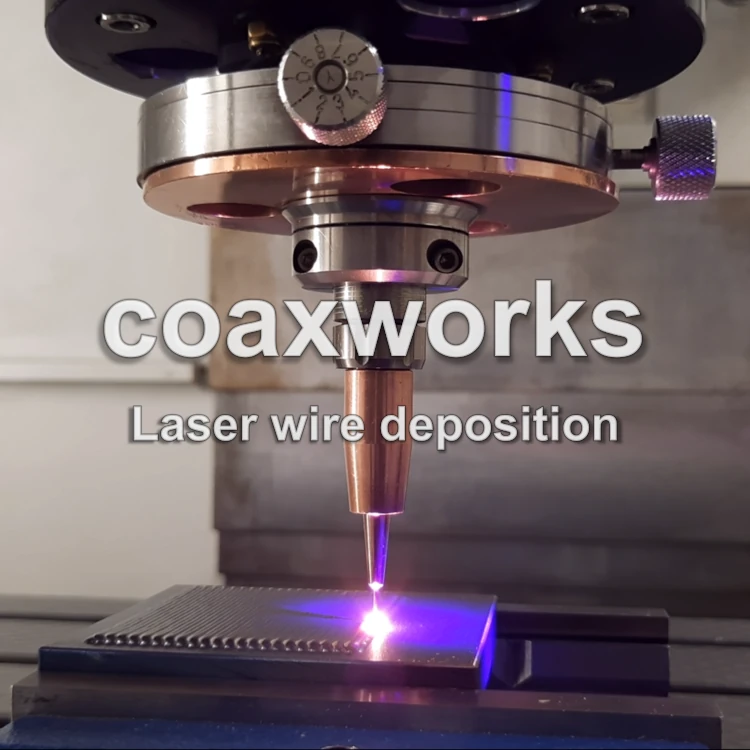

What does coaxworks manufacture?

Laser welding head wireM

The coaxial laser welding head wireM is an interchangeable equipment for robot and CNC laser processing machines. It convinces in research and teaching as well as in the industrial environment with a compact design, simple operability and durable robustness. The latest version offers numerous configuration variants and even more technical interfaces to peripherals.

coaxworks shielding gas chamber SGC500

The SGC500 portable shielding gas chamber is a separate machinery component for CNC and robot-based laser wire welding processes. By means of a flexible foil tent and an additional adapter on the laser welding head, a high-purity shielding gas atmosphere can be set up. Bottom connections for a continuous flow of inert argon gas allow a stable oxygen content of less than 20 ppm after only 20 minutes. The suitable processible component size is approximately 150x150x150 mm³.