Laserline has introduced MultiWire cladding with up to three wires using its OTS and OTZ series processing optics and the advantages are many.

- Feeding up to three wires at once enables far higher deposition rates so it’s more efficient.

- Multiple wires make the process independent of direction of the laser so it’s more flexible and adaptable for complex designs.

- Material efficiency is 100% so there is no loss; nor is the workpiece contaminated by cladding material.

- Wire materials are cheaper than powder materials.

Technical Director Dr. Cédric Chaminade of Raymax Applications, which distributes Laserline in Australasia, says its processing heads are designed for industrial material processing and to be used in combination with Laserline’s diode lasers. “The Multiwire is compatible with up to 12kW of laser power and commercially available wires (1.0, 1.2 and 1.6mm), targeting corrosion, protection and wear protection of large areas, 3D printing with greater wall thickness and roller cladding.”

Laser cladding with MultiWire

The process

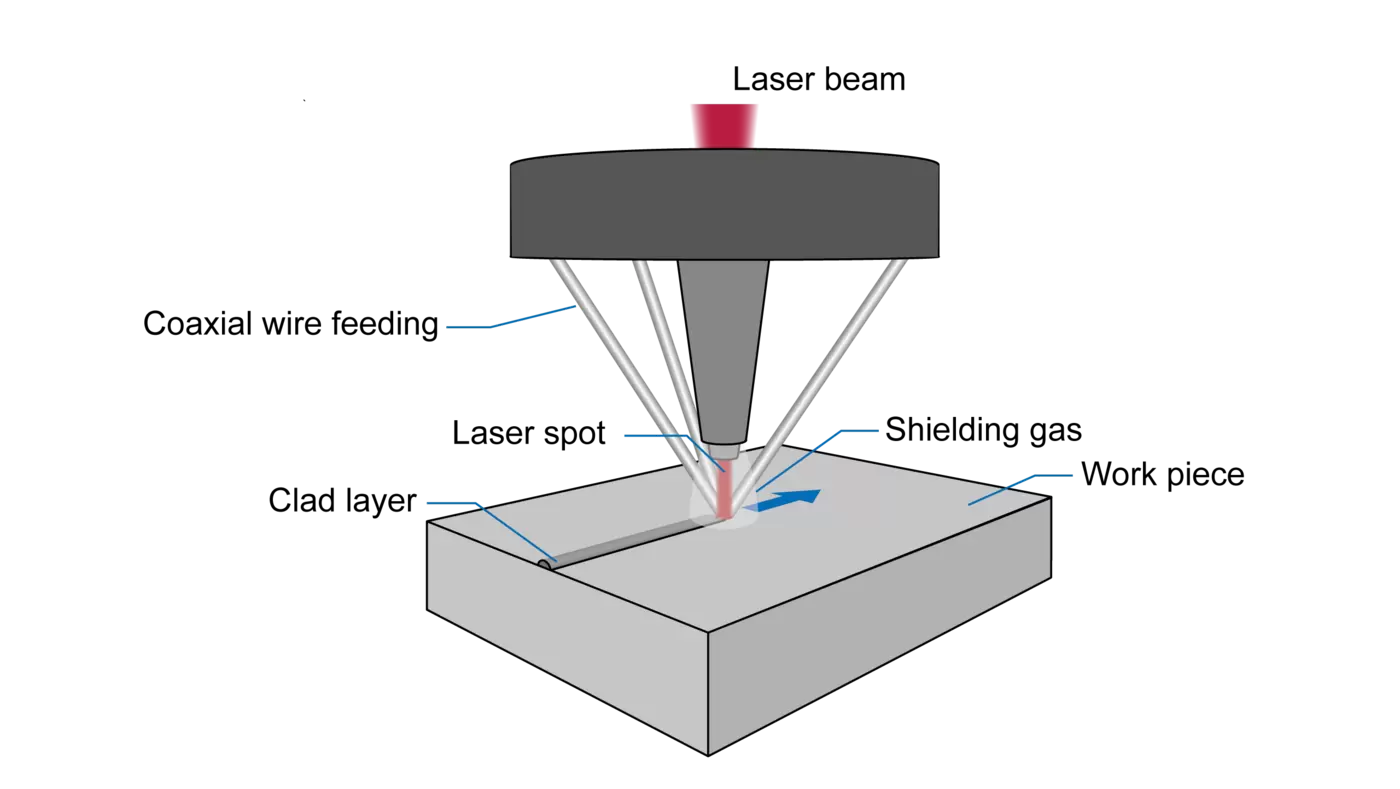

Wire-based laser cladding is done with MultiWire processing optics. The laser beam creates a molten pool on the workpiece, to which cladding material from up to three wires is simultaneously fed. The result is more durable than thermal-spray coatings and, unlike hard chrome plating, is harmless to health.

Hot wire option

Electrical preheating of wires means less laser power is needed because the wire is almost completely melted before going into the weld pool. This has further positive effects:

- Reduced laser power and energy savings due to faster deposition

- Less mixing of the base material

- Even temperature distribution across wire and workpiece

- Virtually no reworking required - efficient process, high quality

To find out more about the MultiWire cladding process, call Raymax, Laserline’s Australasian distributor, on (61 2) 9979 7646

OR come see us at Raymax stand MS110 at AMW in Melbourne, May 6-9, Melbourne Convention and Exhibition Centre to find out about photonics equipment that is transforming manufacturing – including Applied Spectra, HySpex, Amplitude and Viavi.